address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

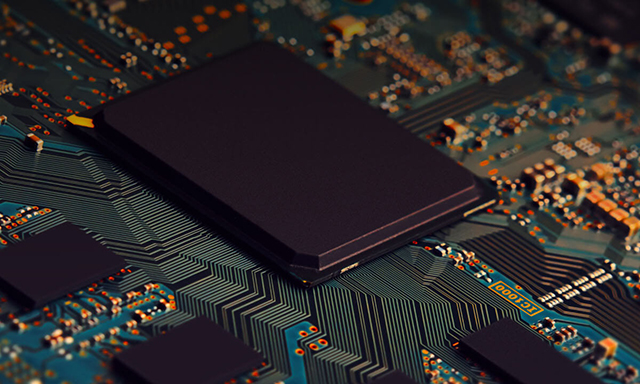

What is the difference between SMT patch processing and DIP plug-in processing?

SMT is to print the components on the PCB board of red glue or solder paste through the placement machine, and then solidify through the soldering furnace; DIP plug-in is to insert the components into the PCB board hole with DIP structure, and there are manual plug-ins and manual plug-ins for DIP plug-ins. AI plug-in, so what are the differences between the two? Let's talk about it in detail below by the editor of KFPCBA.

SMT patch processing is currently the most popular technology in the electronic assembly industry. SMT patch processing features: 1. High assembly density, small size and light weight; 2. High reliability and strong earthquake resistance; 3. Soldering joints Low defect rate; 4. Good high frequency characteristics, reduce electromagnetic and radio frequency interference; 5. Effectively improve production efficiency and save costs;

DIP is one of the basic components of electronic components, called dual-in-line packaging technology. DIP manual plug-ins have to go through wave soldering to solder the electronic components on the board. For the inserted components, check whether they are inserted incorrectly or missing. Features of DIP plug-in technology: 1. Strong anti-bump performance; 2. Low failure rate and easy to inspect; 3. Product performance is more stable;

SMT patch processing and DIP plug-in have their own characteristics, but they are complementary to each other to form a series of production processes. Only by strictly controlling the products can customers and users realize our intentions. Shenzhen KFPCBA is a one-stop shop The pcba intelligent manufacturing service platform focuses on providing one-stop PCBA services such as PCB proofing, SMT proofing, and component purchasing, realizing PCB, BOM materials, SMT online pricing and ordering to product delivery. ...

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: