address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

High-frequency boards for low-density designs can be single-layer PCBs

Even though it makes more sense to pack multiple circuits into a single board, some applications don't need complex circuitry. Simple devices like calculators have low-density circuit designs that require few electrical pathways, so a single-layer PCB is sufficient.

The circuit boards are also cheaper than the multi-layer type, so there is some incentive to use them in your project. With that in mind, here's all you need to know about single-layer boards.

What is a Single Layer PCB?

A Texas Instruments SR-56 Calculator PCB

Source: Wikimedia Commons

Also known as a single-sided board, a single-layer PCB features only a single conductive layer on one side of the board.

The other side hosts the electronic components, while a substrate layer forms the boundary between the conductive material and the elements. On the other hand, a protective solder mask and silkscreen layer cover the conductive side.

This is the simplest printed circuit board type compared to other designs and is best suited for simple low-density designs. Additionally, the PCB has no plated-through holes, and each line must have its path.

Types of Single Layer PCB

Single Layer Rigid PCB

Single Layer Flexible PCB

A flexible PCB

Source: Wikimedia Commons

Single Layer Rigid-Flex PCB

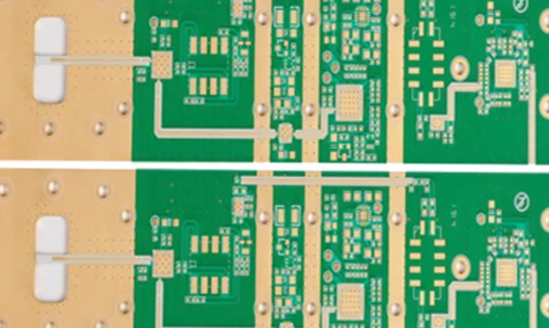

Single Layer High-Frequency PCB

A high-frequency circuit board

Single Layer Aluminum Backed PCB

1 Layer PCB Stack Up

Even though it is a single-layer circuit board, this PCB type has four layers in total. These include the following: silkscreen, solder mask, base, and conductive layers.

Single-sided PCB layers

However, the two main layers are the conductive and base layers.

Copper Layer

Also known as the copper layer, the task of the conductive layer is to transmit electrons and signals. As the name suggests, it usually consists of copper because it is the most affordable and feasible material. But silver and gold are also good conductors.

Base Layer (Substrate)

In addition to creating a platform for the other layers, the base layer holds the component assembly. FR-4 is the most commonly used material. But some PCBs have metal bases, and the material used can classify the circuit board.

Base Material for Single Layer PCBs

While FR-4 and metal are the most common, the other base materials for single-layer boards include Composite Epoxy Material (CEM), polyimide, and Teflon. Each has distinct features, characteristics, benefits, and drawbacks, suitable for different applications.

Single-Sided PCB Manufacturing Process

The process involves the following steps:

Order placement plus DFM check

Circuit board cleaning and cutting

PCB drilling and cleaning

Copper plating

Circuit printing

Etching

Automatic Optical Inspection

Solder mask application

Silkscreen application

Surface finishing

Flying probe test

Printed circuit board manufacturing

Advantages of Single-Sided PCB

Simple design

Easily available

Low cost

Easy to manufacture (short lead time)

Easy high volume production

Not easy to short the circuit

Easy to install

More reliable

Easy testing and repairing

Disadvantages of Single-Sided PCB

Wide size and weighty

Slow transmission speeds

Not ideal for complex circuits

Low operating capacity

Single-Sided PCB Applications

Single-sided PCB applications include the following:

Home appliances like coffee machines

Calculators, printers, radios (stereo equipment), mobile phones, and cameras

LED lights

Solid State Drives and sensors

A SATA SSD printed circuit board with electronic components

Source: Wikimedia Commons

Power supplies

Packaging equipment and vending machines

Relays

Surveillance equipment

Timer circuits

Deciding Whether You Need a Single-Layer or Multilayer PCB

The primary determining factor is the task requirements because the type of PCB should fit into your project. Therefore, you should ask yourself these questions:

What is the level of functionality for the project? If it is complex, go for the double-sided PCB or multi-layer board.

What is the maximum PCB size that can fit into your project? Multi-layer circuit boards pack several circuits in a small area, so they are the better option if you have limited space.

Is durability a key factor? If yes, pick the multi-layer PCB. Since it has multiple layers, it is thicker, making it stronger and more durable.

What is my budget? Single-sided circuit boards are easier to make, hence more affordable than multi-layer PCBs.

How fast do I need the PCB? Since single-sided printed circuit boards are easier to manufacture, they have a shorter lead time. Thus, you will get the board faster than a multi-layer board after ordering.

Multi-layer pcb layers

PCB Solutions: 1 Layer and Multilayer PCB Manufacturer

Since making PCBs is not an easy task, knowledge, skills, experience, and resources are vital factors that your PCB manufacturer should have.

At OurPCB, we have been manufacturing and assembling printed circuit boards since 2005. During this period, we have grown those factors and become the best PCB manufacturer.

Therefore, we can build you any single, double, or multi-layer printed circuit board that meets the highest quality standards.

Additionally, we only use authentic components sourced from reliable and well-known manufacturers to ensure the final assembly is of the best quality.

Contact us today by filling out a simple form and uploading your PCB design files. We'll get back to you and keep you in the loop throughout the manufacturing process.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: