address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

Process and precautions for factory surface assembly of PCB smt quick samples

Process and precautions for factory surface assembly of PCB smt quick samples

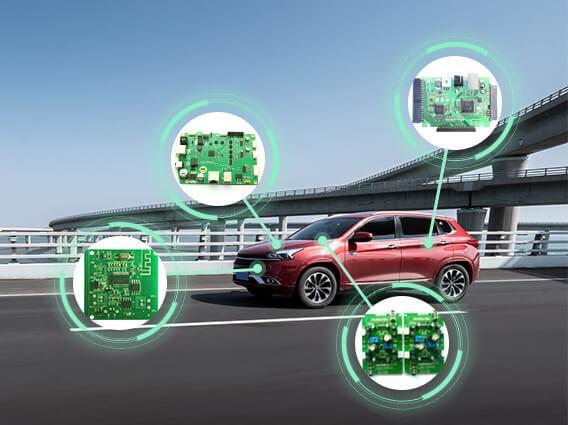

Generally, there are still many points to be paid attention to in the production and processing of smt rapid proofing factories . Operate according to the production standard to ensure the quality and reliability of the product. SMT is Surface Mount Technology (Surface Mount Technology) (abbreviation), which is the most popular technology and process in the electronics assembly industry. Electronic circuit surface assembly technology (Mount, SMT), known as surface mount or surface mount technology. It is a kind of non-lead or short-lead surface mount components (referred to as SMC/SMD, Chinese called chip components) mounted on the surface of the printed circuit board (Board, PCB) or the surface of other substrates, through reflow The circuit assembly and connection technology of soldering and assembly by methods such as soldering or dip soldering. Under normal circumstances, the electronic products we use are designed by pcb plus various capacitors, resistors and other electronic components according to the designed circuit diagram, so all kinds of electrical appliances need various smt rapid proofing processing technology to process.

What does smt proofing mean_General proofing digital proofing_smt proofing

Precautions for smt rapid proofing in smt rapid proofing factory

What does smt proofing mean_General proofing digital proofing_smt proofing

1. The cleaning of the welding surface must use a professionally configured cleaning agent.

2. The circuit boards after smt rapid proofing cannot be stacked, otherwise it will cause physical damage to the boards.

What does smt proofing mean

3. Components and PCBA that are sensitive to EOS/ESD need to be marked with the appropriate EOS/ESD mark.

4. Keep the operating table clean and tidy. There should be no food or drink in the working area. Smoking, cigarettes and ashtrays are strictly prohibited.

5. Reduce the operation process of components to the minimum limit to prevent risks.

6. The soldered surface of the circuit board cannot directly touch the human skin, otherwise the grease will affect the reliability of the soldering.

SMT patch, SMT patch processing , SMT patch processing factory, electronic smt patch processing, patch processing factory, patch processing, PCB patch processing factory, PCB patch processing, pcba proofing, pcba urgent proofing, smt fast proofing, Shenzhen patch processing, pcba small batch proofing, SMT patch proofing, smt patch factory, Shenzhen pcba, pcb proofing factory, China Shenzhen pcb proofing

KFPCBA one-stop PCBA intelligent manufacturing platform, R&D model/small batch, SMT patch, PCB proofing, DIP welding processing, PCB board making , full set of electronic components purchasing, partial purchasing one-stop PCBA manufacturing services. Friendly reminder: The data and information of each information are for reference only, please contact us for the most accurate information, thank you!

Generally, there are still many points to be paid attention to in the production and processing of smt rapid proofing factories . Operate according to the production standard to ensure the quality and reliability of the product. SMT is Surface Mount Technology (Surface Mount Technology) (abbreviation), which is the most popular technology and process in the electronics assembly industry. Electronic circuit surface assembly technology (Mount, SMT), known as surface mount or surface mount technology. It is a kind of non-lead or short-lead surface mount components (referred to as SMC/SMD, Chinese called chip components) mounted on the surface of the printed circuit board (Board, PCB) or the surface of other substrates, through reflow The circuit assembly and connection technology of soldering and assembly by methods such as soldering or dip soldering. Under normal circumstances, the electronic products we use are designed by pcb plus various capacitors, resistors and other electronic components according to the designed circuit diagram, so all kinds of electrical appliances need various smt rapid proofing processing technology to process.

Precautions for smt rapid proofing in smt rapid proofing factory

1. The cleaning of the welding surface must use a professionally configured cleaning agent.

2. The circuit boards after smt rapid proofing cannot be stacked, otherwise it will cause physical damage to the boards.

3. Components and PCBA that are sensitive to EOS/ESD need to be marked with the appropriate EOS/ESD mark.

4. Keep the operating table clean and tidy. There should be no food or drink in the working area. Smoking, cigarettes and ashtrays are strictly prohibited.

5. Reduce the operation process of components to the minimum limit to prevent risks.

6. The soldered surface of the circuit board cannot directly touch the human skin, otherwise the grease will affect the reliability of the soldering.

SMT patch, SMT patch processing , SMT patch processing factory, electronic smt patch processing, patch processing factory, patch processing, PCB patch processing factory, PCB patch processing, pcba proofing, pcba urgent proofing, smt fast proofing, Shenzhen patch processing, pcba small batch proofing, SMT patch proofing, smt patch factory, Shenzhen pcba, pcb proofing factory, Shenzhen pcb proofing

Lingzhuo one-stop PCBA intelligent manufacturing platform, R&D model/small batch, SMT patch, PCB proofing, DIP welding processing, PCB board making , full set of electronic components purchasing, partial purchasing one-stop PCBA manufacturing services. Friendly reminder: The data and information of each information are for reference only, please contact us for the most accurate information, thank you!

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: