address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

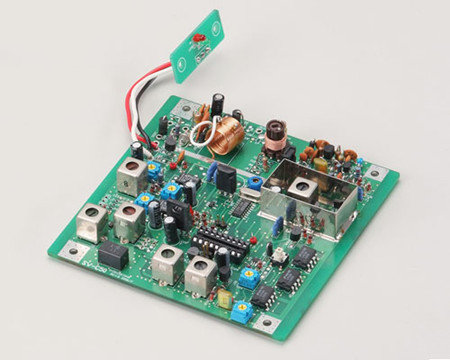

Copper Plating Process Of Printed Circuit Boards

Various substances in the electroless copper plating process of printed circuit boards

During the physical nickel plating process, printed circuit boards in 深圳 Circuit Board Processing Factory will continuously consume various substances in ammonia water. Circuit board design and manufacture should be analyzed in time according to the production volume in the process of operation. The stability of lye.

With the continuation of production, the physical nickel plating lye is used repeatedly, and the addition of physical substances will gradually increase the various impurities in the lye. Part of the old lye should be properly replaced after a certain production cycle to make the physical nickel plating The activity of nickel lye is reduced to ensure the quality of physical nickel plating.

After the physical nickel plating work is finished, the pH value of 深圳 circuit board production is adjusted to below 10, and after the physical nickel plating ammonia water reaction stops, filter in time to remove the particulate matter in the filtrate. And under constant stirring, lower the pH value to the technical range.

In fact, whether it is physical thin copper plating or physical thick copper plating, the physical nickel plating lye should be correctly prepared according to the process specifications; the process conditions should be strictly controlled; the physical nickel plating lye should be carefully maintained; the printed board should be strengthened. The pre- and post-treatment of physical tin plating. Those are the key to ensure the quality of the product, according to Shenzhen circuit board manufacturers .

Lanzhou pcb circuit board manufacturer teaches you how to deal with burrs on the surface of the circuit board proofing board!

Many times, the circuit board is damaged due to various reasons, which not only affects the product quality but also affects the speed of circuit board proofing. If there is a burr on the surface of the circuit board, how to deal with it?

There are usually several ways: pay attention to the quality of the pre-coating for parts with complex shapes, and avoid the formation of a replacement copper layer; add potassium iodide regularly, and stir vigorously when adding; test and ensure the content of sulfur | The role of manganese; the anode with unqualified sulfur content cannot be used; the area ratio of anode and cathode should not be greater than 1.5:1; the anode sleeve should not be too thick to prevent clogging (double-layer nylon cloth is suitable); between the anode hook and the pole The contact should be good. Nanjing pcb circuit board manufacture, Chongqing pcb circuit board design please contact us KFPCBA!

With the continuous development of science and technology, integrated circuits have gradually become a circuit mode commonly used in circuit board assembly. So, what are the reasons why integrated circuits are so popular? It depends on its characteristics Speaking of.

The circuit board assembly of integrated circuits has the advantages of small volume, light weight, fewer lead wires and soldering points, long life, high reliability, good performance, etc., and low cost for mass production. Shenzhen pcb circuit board design it in addition to Industrial and civilian electronic equipment such as tape recorders, televisions, computers, etc. are widely used, and are also widely used in military, communication, remote control, etc. Using integrated circuits for circuit board assembly, the assembly density can be improved compared to transistors Dozens of times * thousands of times, the stable working time of the equipment can also be greatly improved.

Electronic components are components of electronic devices and large electrical machines and instruments. They are often composed of several parts and can be used in similar products; they often refer to individual parts in industries such as household appliances, radios, and instruments, such as capacitors and transistors. , hairspring, clockwork and other sub-components. The common ones are thyristors, etc.

Electronic components include: internal resistance, capacitors, potentiometers, electron tubes, radiators, electromechanical devices, connectors, semiconductor discrete components, electroacoustic components, laser components, electronic display components, photoelectric components, sensors, power supplies, switches, micro-special Motors, electronic transformers, relays, printed circuit boards, integrated circuits, various circuits, piezoelectric, crystals, quartz, ceramic magnetic materials, base substrates for printed circuits, special materials for electronic functional processes, electronic adhesive (tape) products, Electronic physical materials and parts, etc.

In terms of quality of electronic components, there are CQC certification in China, UL and CUL certification in Germany, VDE and TUV in Italy, and CE in the European Community to ensure the qualification of components.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: