address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

How to choose PCB board and what should be paid attention to when testing PCB board?

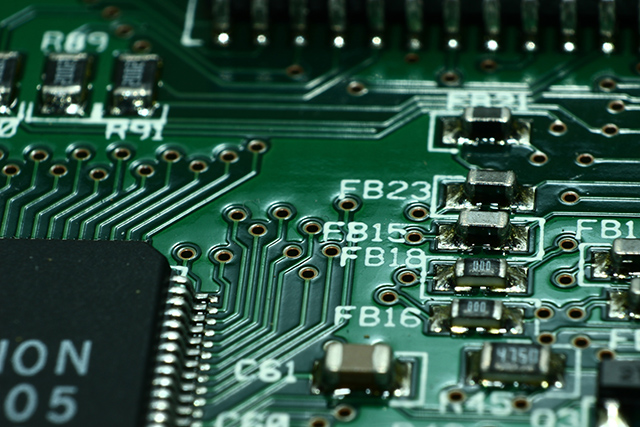

PCB board is also called "PCB printed circuit board". PCB boards can be divided into single-sided, double-sided, and multi-layer boards according to their levels. They have the characteristics of high density, good safety, thin thickness, and good bending properties. They are widely used in In communications, automotive electronics, consumer electronics, aerospace and other fields, the manufacturing quality of PCB boards not only directly affects the reliability of electronic products, but also affects the integrity of signals transmitted between chips.

With the rapid development of electronics, communications, aerospace and aviation, the demand for PCB boards continues to increase. In order to enhance their core competitiveness, many manufacturers monopolize the market with low prices, but behind the low prices are choosing to reduce material costs and craftsmanship. Cost, which leads to uneven PCB boards on the market. Faced with defective PCB printed circuit boards on the market, it can be distinguished from the appearance of the PCB boards and the quality of the PCB boards themselves. In terms of appearance identification, we can observe the thickness of the PCB board, the appearance of soldering, and the light and color to distinguish.

PCB board is the key electronic interconnection of electronic products and the substrate loaded by various electronic parts. All electronic equipment cannot do without PCB board. Therefore, a high-quality PCB board must have the copper skin not easy to fall off under high temperature; PCB board The line width, line thickness, and line distance of the circuit meet the requirements; the electrical connection of the PCB board must meet the requirements, the appearance of the PCB board should not be deformed, and it must have high temperature, high humidity and resistance to special environments.

The soldering quality of the components on the PCB directly affects the performance of the product. Therefore, the quality inspection and testing of the PCB is a necessary part of the quality control of the PCB manufacturer. Pay attention to the following points when inspecting PCB boards:

1. Insulation performance of the electric soldering iron: do not use the electric soldering iron to solder, make sure that the soldering iron is not charged.

2. Do not cause a short circuit between the pins: When measuring voltage or using an oscilloscope probe to test the waveform, do not cause a short circuit between the pins of the integrated circuit due to sliding of the test leads or probes.

3. Pay attention to the heat dissipation of the power integrated circuit: do not work with the radiator in a high-power state.

4. Reasonable detection of PCB board leads: If you need to add external components to replace the damaged parts of the integrated circuit, small components should be selected, and the wiring should be reasonable to avoid unnecessary parasitic coupling.

5. Guarantee welding quality: carefully check the integrated circuits that have been welded, confirm that there is no confirmation and no solder adhesion phenomenon, and then turn on the power

The demand for terminal electronic products to be light, thin, short, and multi-functional has promoted the rapid improvement of the product performance and integration of electronic components. This also puts forward higher and more refined requirements for the processing and materials of PCB. Kuafa Intelligent Manufacturing provides smt patch proofing, pcb proofing, PCBA processing, SMT patch processing, electronic components purchasing, DIP post-welding and assembly testing one-stop proofing and small and medium batch manufacturing services.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: