What Are Medical PCBs?

Medical PCBs are circuit boards used to run the circuitry of electrical equipment used in the medical industry. As medical equipment becomes more computerized, complex, and compact, they require boards with high-density circuits.

Therefore, a medical printed circuit board should pack electronic components and connections in a compact space while maintaining reliability. So most of them are HDI (High-Density Interconnect) PCBs.

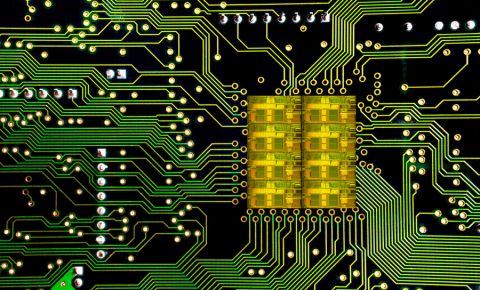

A high-density PCB

Also, most medical devices do not conform to the usual designs. Therefore, their PCB size and shape should match the device, meaning most PCBs for critical medical equipment are flex or rigid-flex.

A flexible PCB

Applications of Medical PCBs

Cardiovascular medical equipment (defibrillators, pacemakers, heart monitors)

A pacemaker

Medical imaging systems (ultrasonic equipment, MRI, CT scans)

Blood glucose monitors

Body temperature monitors

Electrical muscle stimulation equipment

Medical instruments for collecting research data and test results

Medical PCB Technologies

As medical devices advance, they contain at least one of the following technologies.

IPC Class 3

Class three boards for high-performance electronic products should have no downtime. Reliability is a critical factor here, meaning medical PCBs should have the following features.

Zero annular ring breakouts

1-mil minimum plating in the thru-holes

Tight tolerance on conductor width and spacing

Via-in-Pad/ HDI

A high-density interconnection makes it possible to reduce the printed circuit board size.

5-mil Spaces/Lines and Below

IPC class III needs minimum line width reduction during processing. So the medical PCB manufacturer should have laser-direct imaging and other such equipment to achieve the required production yield.

An MRI scanner

Laminate Requirements

FR-4 is the most typical PCB laminate. But medical boards are not like the usual PCBs. Therefore, you require an Electronics Contract Manufacturer (ECM) with expertise in ceramic, polyimide, Teflon, and other high-quality materials that meet the board's unique requirements.

Free PCB DFM Devices

DFM (Design for Manufacturability) compiles all PCB layout topologies to minimize issues that might arise during fabrication and assembly. Doing DFM before making prototypes is essential to avoid returning to the drawing board.

A blood sugar monitor

Tips for Medical PCB Design and Assembly

Consider these factors if designing medical devices with PCBs.

Safety First

Medical devices might get exposed to extreme temperatures, liquids, or shock in their operating environment. For instance, implantable devices like pacemakers live inside the human body. And any malfunction caused by this exposure can be catastrophic.

A pacemaker placement in the human body

Additionally, these devices need to be easy to disinfect and clean. So they should have an enclosure material that can withstand ozone cleaning and disinfectants. Stainless steel is the most typical material used for this task. Also, the enclosure or coating should protect the PCB from dust, contaminants, corrosion, moisture, and salt spray.

Lastly, there is the noise emission issue. Critical devices, such as pacemakers, should not experience interference.

Comply with the Standards

As stated earlier, medical equipment and devices fall under class 3 electronics. So they must adhere to strict standards.

Besides looking for a manufacturer who can meet all class 3 requirements, it is vital to do detailed record keeping of test and inspection processes. And you can use FDA or ISO standards as benchmarks for this process.

If you rely on your ECM to do the record-keeping, ensure they are capable and can handle the process. Keep in mind these record-keeping mandates are open-ended and might require you or your ECM to keep them for long periods.

Other quality standard requirements include installation, operation, and process qualification. For instance, if fabricators move machines physically within their premises, they must re-qualify them in their new locations. Why? They must prove nothing changed and the manufacturing process runs just as or better than before.

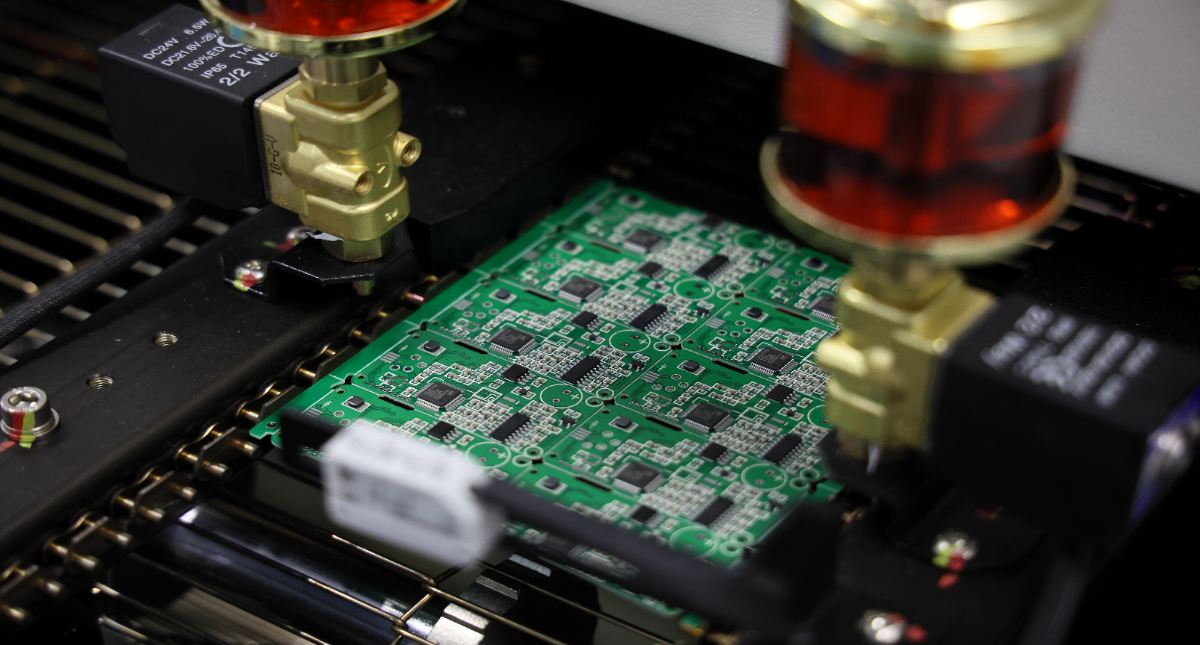

A PCB assembly line

Most ECMs like taking shortcuts here to cut costs. So it is your responsibility to vet PCB manufacturers to get a reliable ECM that builds consistent quality products.

Be Ready To Live With Obsolescence

Reliable PCB fabricators should predict component obsolescence using component database software like SiliconExpert. And they should always be on the lookout for component availability changes, especially for life-saving products.

A CT scanner

If you find out at the last minute that a component has gone obsolete and the device requires a significant design change, you might have to go through the approval process again. And as you know, approval from federal agencies takes time.

Thru-Hole or SMT?

Knowledgeable and experienced medical-grade PCB manufacturers will implement the right technology that meets your needs. Most modern PCB designs use SMT electronic components to create compact boards.

Thru-hole and SMT components on a PCB

However, thru-hole assemblies are critical for power requirements and connectors due to their physical strength. So the manufacturer should implement the best technology that suits each board section.

How Small Can You Go?

The general trend with electronic devices is shrinking. Therefore, your contract manufacturer should build compact packages that fit in tiny equipment. And they should have the required machines for placing components on compact boards. But there are limits. For instance, considering surface-mounted parts, the smallest package in the market currently is 0.25 mm × 0.125 mm.

Since there are multiple factors to consider, you should get a reputable, skilled, experienced, and trustworthy PCB manufacturer.

Considerations for Manufacturing Medical Equipment PCBs

Assess and plan the lifespan of medical devices during PCB design

Plan quick timelines for product launches because the market is competitive

Do a detailed corner case evaluation during the medical device's operation

Put user safety as the primary concern during the design, fabrication, and assembly of medical PCBs

Ensure the PCB meets all medical industry and regulatory standards

Output consistency is vital when designing monitoring or diagnostic medical electronic devices

Usability is crucial to consider when designing implantable or wearable devices

Understand the effects of the debris left behind by medical devices and follow up with the required maintenance steps

Wrap Up

There you have it! Medical PCBs have grown in complexity to enhance the performance of modern medical equipment. So you must adhere to strict safety and industry standards to ensure the devices are safe for internal and external human body use. We hope the tips above will help you in the medical PCB design and assembly process, and you should consider us for your ECM. for further information about your PCB.

tel:+86-18825224069

tel:+86-18825224069 email:

email: address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china