address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

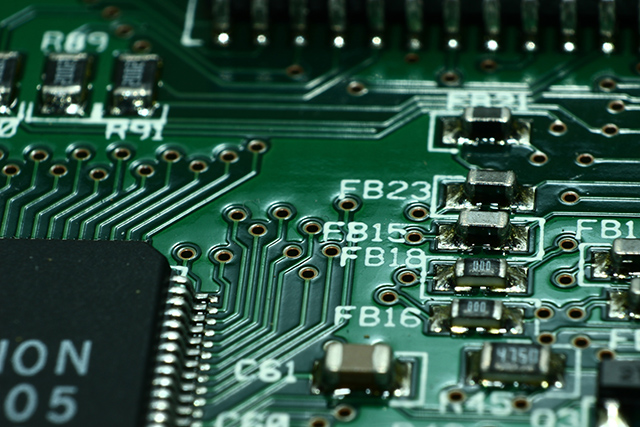

What should be paid attention to in small batch PCBA assembly?

What should be paid attention to in small batch PCBA assembly?

This is the process of partICipating in PCBA production and assembly by reducing costs while ensuring high quality. Here, various technologies are used in these processes to maintain quality and reduce costs.

Technology used to ensure small batch PCB

As mentioned earlier, the purpose here is to utilize unique technologies in SMT processing. This means that you must find some unique technology to help you assemble all the components of a PCB. The following are some of the techniques used when assembling small batches of PCBs while still maintaining high quality.

Minimize number of layers

This is a very important technology in reducing the costs associated with SMT Assembly. This requires fewer layers. In this way, the cost of components and materials will certainly be reduced

Be careful when arranging

When assembling in the SMT chip factory, care must be taken when arranging the number of vias. By doing so, errors in any form will be eliminated or reduced, thereby reducing costs.

Proper size

You must be very careful when adjusting and planning important details such as rings and holes. We mean to keep perfect. When you keep the board size to the minimum, you should avoid mistakes

Prevention of internal cuts

The SMT Chip prevents internal cuts on the printed circuit board. This will help eliminate the costs involved in repairing internal incisions. With this, you will be able to save material costs for internal wiring and through hole drilling.

Select the most appropriate via

It is very important to select the most appropriate via without causing any complexity in the PCB assembly process. For this reason, you may buy through-hole at a higher price, but in the long run, it will save you a lot of money.

Adhere to basic options

Always adhere to the basic knowLEDge of PCB assembly, and do not take risks in custom design. Keep the normal shape of PCB, and do not test PCB with unusual shape.

Maintain industry standards

Make sure that the standard requirements are maintained and that you do not venture into uncharted territory. In this case, only use the correct standard components, dimensions and select the correct surface treatment.

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: