address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

address:201, Factory 6, Longhui Industrial Park, Fuqiao 3rd District, Xinhe Community, Fuhai Street, Baoan District, Shenzhen china

What factors affect the quality of SMT patch processing?

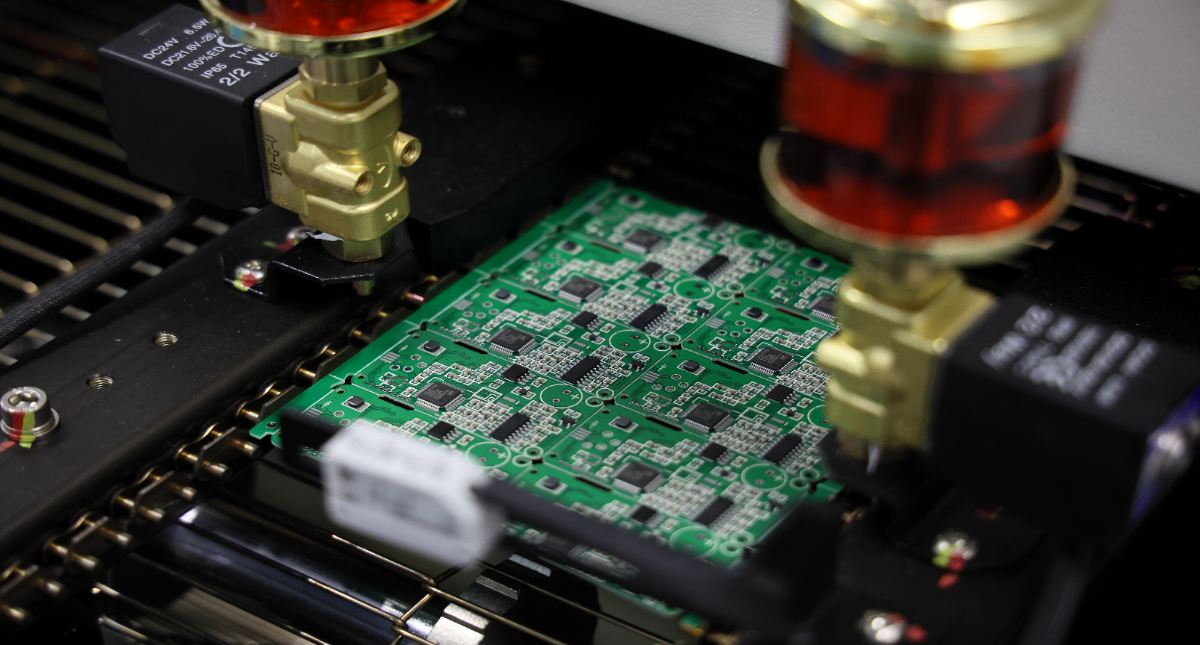

The SMT patch processing process is complicated. The quality of SMT patch processing is related to the stability of the finished product and product life. Therefore, when SMT patch processing is performed, it is necessary to strictly control the process of each link. Then what factors affect SMT How about the quality of patch processing?

Components: The type, model, nominal value and polarity of the components must fully comply with the requirements of the product assembly drawing and schedule.

Position: During the placement process, it is necessary to ensure that the ends or pins of the components are aligned or centered, the solder ends of the components contact the solder paste pattern, and the placement position of the components is accurate.

Pressure: During the SMT mounting process, the pressure should be controlled. Do not be too low or too high. If the pressure is too low, it is easy to cause the solder paste to not stick to the components, resulting in position shift during reflow soldering. When the pressure is too high , Easy to cause solder paste adhesion.

PCB circuit board: PCB board is used as the substrate for SMT chip processing, and the quality of PCB also affects the quality of SMT process.

Furnace temperature curve: When the pcb board, components, and solder paste printing are all normal, then the key factor of whether the product is qualified is the curve setting of the furnace temperature.

Equipment: If a worker wants to do his job well, he must first sharpen his tools. When SMT placement, the production equipment and the performance of the production equipment need to be used for placement. Therefore, the equipment is an indispensable method for SMT mass production.

Steel mesh: The setting of the thickness of the steel mesh and the design of the window directly affect the quality of SMT patch processing.

SMT patch manufacturer: Choosing a high-quality patch manufacturer can guarantee the quality of SMT patch processing. The difference in SMT patch processing technology will directly lead to the utilization rate, pass-through rate, and yield rate of the equipment.

There are many factors that affect the quality of SMT patch processing. In order to ensure the straight-through rate of products, a professional SMT patch processor should be selected. As a one-stop pcba smart manufacturing service provider, it has more than 20 years of industry experience. Focus on providing one-stop services such as SMT patch proofing, PCB proofing, SMT patch processing, PCB manufacturing, and component purchasing and purchasing. At the same time, the proofing service provided by Kuaifa Zhizao can be delivered in 23 hours, allowing you to occupy the market first!

-

No comment

tel:+86-18825224069

tel:+86-18825224069 email:

email: